The average consumer may think that the pharmaceutical industry follows a simple two-step process: develop medicine and then sell it to the masses. Pharma leaders, on the other hand, know there is a much more complex chain of processes that includes packaging, transporting, and distributing medicine before it ever reaches the consumer.

Medicine packaging machines are essential tools for product preparation. Understanding the applications of these machines, as well as the equipment they use and the steps to take both before and after the packaging process, helps medication manufacturers establish a more efficient and compliant pharma production line.

Key Takeaways:

- Packaging machines in the pharmaceutical space can massively boost the production of vaccine vials and soft gel capsule blister packages.

- Vaccine manufacturers rely on high-quality vial loading trays to efficiently feed vials into the packaging machine and store the finished product afterward.

- Soft gel capsules must thoroughly dry in a specialized drying tray before workers can load them into a blister packaging machine.

What Are the Applications of Medicine Packaging Machines?

Pharmaceuticals represent an essential industry and one that only grows as new innovations emerge and consumer bases expand. State-of-the-art medicine packaging machines therefore become a necessity for manufacturers that experience success in their operations and need suitable solutions to upscale their productivity.

Research from MarketsandMarkets shows the global pharmaceutical packaging equipment market was worth an estimated $8.9 billion in 2023, with a projected increase to $12.4 billion by 2028. The observable ubiquitousness of this technology demonstrates how necessary it is as an investment for pharmaceutical producers, whether they use hand-operated tools for packaging or large-scale automated machines.

One popular application for these machines is to package soft gel capsules into blister packs. A medicine packaging machine can receive large quantities of encapsulated medicine and feed the capsules evenly into a roller to seal the product into the blister packages that will make their way to consumers.

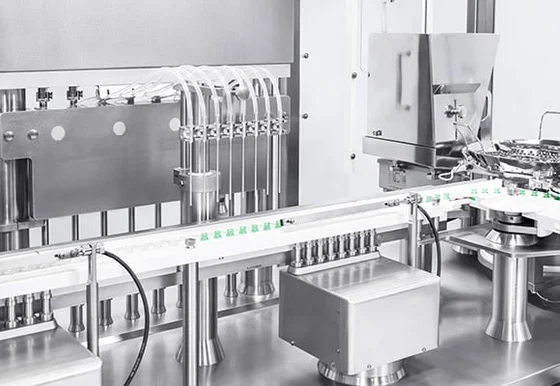

In another important area in the industry, vaccine manufacturers typically distribute their medicine products in vials, which require a different type of packaging machine. Vial-filling machines receive trays of empty vials and shift the trays along to fill each vial or row of vials according to a programmed pattern.

What Is the Medicine Packaging Process?

The specific processes for medicine packaging differ depending on the type of medication the machine is packaging. For both vaccine vials and soft gel capsules, there are steps that manufacturers should follow before and after packaging to ensure safety and product retention.

Packaging Process for Vaccine Vials

When using a medicine packaging machine to fill vials, quality is paramount for both the vials themselves and the vial loading trays that line workers feed into the machine. These trays should be easy to load, durable, highly reusable, and easy to clean.

Hurst injection-molded vial loading trays distributed by Chemtech International are 3-sided and feature a removable, easy-to-slide gate to facilitate easier loading and unloading. These polycarbonate trays lend speed and cost-efficiency to the packaging process by being easy to clean and resistant to corrosive substances.

Hurst also manufactures custom vacuum-formed vial loading trays that provide production tooling at a fraction of the cost of injection mold tooling. In addition to these trays, Chemtech International offers stainless steel vial loading trays from Hurst available in two different finishes based on the vaccine manufacturer’s needs.

The next steps after using a medicine packaging machine to fill vaccine vials are to store and eventually transport the filled vials. Hurst trays are lightweight yet bear a high weight-carrying capacity. Hurst trays will not bend, dent, or crack under heavy loads, making them reliable for stacking and transporting the finished product.

Packaging Process for Soft Gel Capsules

Before soft gel capsules are ready for packaging, they must go through a drying and curing process after encapsulation. Due to a high moisture content, gel capsules that do not properly dry will be prone to sticking and marking. This makes it difficult or impossible for the medicine packaging machine to separate moist gel capsules that adhere to one another in the feeder.

Chemtech International distributes soft gel capsule drying trays designed to prepare encapsulated gels for packaging. Thoughtful engineering results in drying trays that improve airflow for quicker drying. Contoured edges and rounded corners stop moisture or residue from accumulating, preventing contamination and marking.

The soft gel capsule drying trays provided by Chemtech International feature a composite construction, making them easy to stack and lift with no risk of damage to the trays themselves. These trays are also highly dynamic and suitable for use in a wide range of temperatures and conditions.

After the drying process, workers can load the soft gel capsules into a soft gel medicine packaging machine. Properly dried and cured capsules will not stick nor incur any markings from pressure or contact as the machine seals them into blister packages.

Choosing the Right Supplier for Medicine Packaging Machine Accessories

The handling of medicine before and after packaging can significantly affect the quality of the product. Mishandling the product or using unsuitable medicine packaging accessories can lead to contamination, defects, or damage during transportation. The right supplies reduce the chances of error to maintain quality.

When using a medicine packaging machine, it is important to follow the right steps and to use the best equipment for the type of medicine the machine is packaging. Contact us for a custom quote for vial loading trays or soft gel capsule drying trays.