Stainless Steel VIAL LOADING TRAYS

What is stainless steel?

Stainless steel is an iron based metal which contains low carbon levels and various levels of chromium. When chromium is exposed to air it forms a protective layer of chromium oxide which keeps stainless steel from rusting.

What type of stainless steel should I use?

Of the over 100 types of stainless steel, type #304 stainless steel accounts for over one-half of USA production. Type 304 is highly corrosion resistant when used within normal temperature ranges, including autoclaving.

Type #316L is a slightly harder stainless steel which contains 2 to 3% molybdenum, a high heat additive. Type #316L is indicated for use in depyrogenating.

Type #316L is a best choice when used in contact with distilled water or chlorides.

What finishes are available?

HURST stainless steel products are generally available in two finishes;

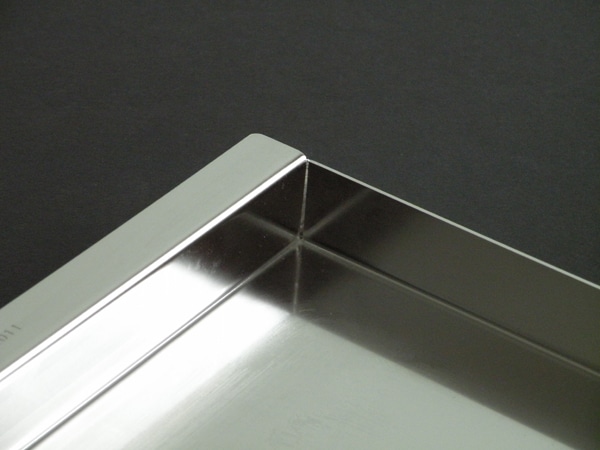

Standard mill finish 2B has an extremely smooth slightly milky surface.

2B is economical and easy to clean. Finish is sometimes expressed as “RA” or arithmetic roughness. RA is the distance (in inches or microns) of deviation from a selected average (mean) surface. The RA of a 2B finish is generally 8.

A #4 finish is a fine grade of brushed metal also known as a Florentine finish.

#4 is a mechanical finish and typically used to finish outside welds. Fine grinding, polishing and buffing can further smooth a #4 finish to a higher luster, however this process is very expensive. The RA of a #4 finish is generally 25-30.

Electro-polishing is available to burn off oxides, brighten, and reduce roughness by 30 to 40%. EP improves sterilization and surface maintenance.

What thickness or gauge of stainless steel is available? How much does it weigh?

| Gauge | Thickness | Weight / sq. ft. |

| 11 | .120″ | 5.040 lbs |

| 14 | .075″ | 3.154 lbs |

| 16 | .060″ | 2.499 lbs |

| 18 | .048″ | 2.016 lbs |

| 20 | .036″ | 1.491 lbs |

What corner welds are available?

Gas tungsten arc welding, also known as TIG welding and fusion welding, is normally used to provide a water tight structure. It is also recommended to eliminate corner cracks and crevasses which may support microbial growth. TIG welding is expensive and demands hand finishing.

Corners may be designed with folding tabs which are tack-welded for structural support. Tab and tack-welded corners are inexpensive and a good choice in a non-sterile environment.

Some thicknesses of stainless steel are rigid enough to be used without welding.

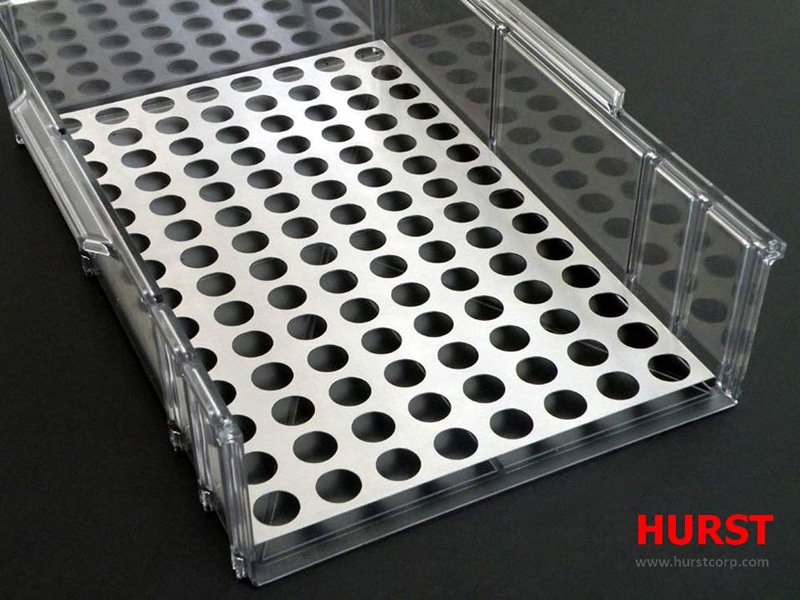

What perforations are available?

Any design or size hole or slot is readily available.

Hurst also manufactures a wide variety of stainless steel tray transport carts in virtually any size and shelf configuration including solid or mesh panels, and sliding or pivoting lockable doors.

Since 1992, Chemtech International Inc. has been a global Supplier of Choice for many domestic and international customers in the pharmaceutical and biotech industries. We are the Exclusive Distributor for Hurst Corp vial loading trays and delivery systems. We offer Polycarbonate, Stainless Steel and ABS materials making our trays stronger and more durable for maximum performance and value. We offer custom design, engineering and manufacturing. No matter what your needs – we have a solution for you. We also represent Mold Fiberglass Tray Company and offer fiberglass composite trays.

Wide Range of Handling & Loading Functions for Large-Scale Vaccine Production

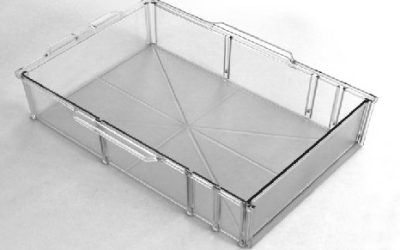

Vial loading trays offer a wide range of handling, storage and transportation functions in pharmaceutical processing. Our patented Hurst vial loading trays are 3-sided with a removable, easy-to-slide gate, which allows for easier loading and unloading.

Durable Vial Loading Trays for Vial Filling Machines

Hurst polycarbonate trays are easier to clean due to their smooth, non-porous surface. Unlike metal materials, which are susceptible to scratching, the polycarbonate material of these loading trays can withstand a wide range of exposure and corrosive substances.

Perfect for For Vaccine Vial Filling Machines

No matter what type of vial loading machine your company uses, our vial loading trays are perfect for any job. Our pharmaceutical trays are lightweight and won’t corrode, dent, or rust like many other low quality non-certified metal vial loading trays on the market.

Easy Stacking Vaccine Vial Loading Trays

The patented Hurst design offers exceptional stacking and weight-carrying capability, and ensures these Hurst trays will not bend, dent, or crack even under heavy loads. Side handles ensure safety and ease of use. The loading trays are also much lighter in weight compared to metal trays, so they can be solidly stacked to save space and streamline the handling and loading process.

Efficient For Large-Scale Vaccine Production

Hurst 316L Electro-Polished Stainless Steel vial loading trays may be used in temperatures ranging from -60° to 250° F (-51° to 121° C) The structural stability can also provide easy, seamless integration into automated machinery and robotic applications, further improving overall efficiency of the manufacturing cycle.

One-Time Expense Vaccine Vial Loading Trays

The lifespan of polycarbonate trays is a major cost benefit compared to plastic, metal and disposable trays. With proper use, cleaning (with standard washers) and maintenance, Hurst vial loading trays are typically a one-time expense for many businesses.

FDA Approval of Large-Scale Vaccine Production Vial Loading Trays

Our vial loading trays are manufactured with the most sophisticated technologies and highest grade materials on the market today. All trays undergo strict quality control procedures to maintain high performance quality and to meet FDA Title 21 C 176.170 regulations.

Get a Custom Quote

Fill out the form below.

The Definitive Guide to Aseptic Filling

As pharmaceutical manufacturers grow their operations and serve an expanding consumer base, they need to find ways to meet higher demands without cutting corners. Without the right solutions in place, there is a very real risk of pathogen exposure to sensitive drug...

Plastic Vial Trays: What You Need to Know

Contamination is a top reason that the U.S. Food and Drug Administration recalls medicinal products. To combat the significant financial losses associated with recalls, you need lab solutions that streamline the manufacturing process for the pharmaceutical and biotech...

How to Select the Right Vial Tray for Your Project

We understand that our customers need vial trays they can rely on to achieve operational efficiency and viability during production and beyond. This is why you’ll find Hurst vial trays within our Chemtech product roster. But how do you make sure you have chosen the right tray for your needs?